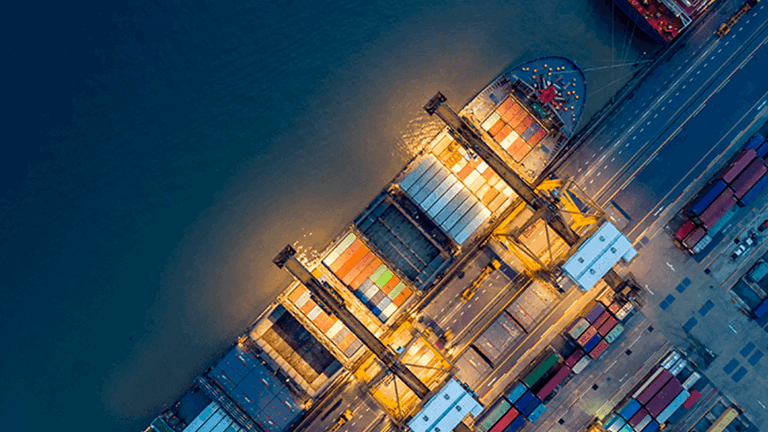

Connecting and Protecting the Global Supply Chain

Why BRCGS?

BRCGS is the leading provider of global supply chain assurance programmes recognised by thousands of customers worldwide.

-

GFSI market leaders

-

Results you can trust

-

The most rigorous schemes

-

The best auditors

Topics of interests

-

BRCGS Training

We offer a range of training courses to support the use of BRCGS Standards for successful implementation and audit.

-

Partners

To support our customers in the BRCGS certification scheme we've created a number of partnerships and partnership programmes.